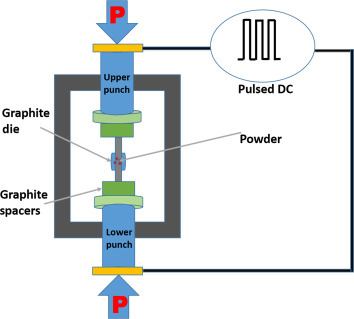

Spark Plasma Sintering (SPS)

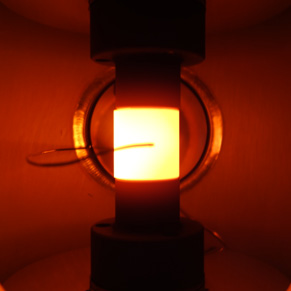

Spark Plasma Sintering (SPS) is also named as plasma-activated sintering, pulse electric current sintering, and pulse discharge pressure sintering. In spark plasma sintering, sintering is realized by subjecting the green compact to arc discharge generated by a pulsed electric current. An electric discharge process takes place on a microscopic level and accelerates material diffusion. The externally applied pressure is generally 30–200 MPa and the heating rate is 100–1000°C min−1. Spark plasma sintering is the most effective densification technique for nanoceramics. One of the most remarkable features of this technique is that the small grain size can be maintained while achieving full densification. For oxides such as MgO, nanoparticles are spark plasma sintered between 700 and 825°C under applied pressure of 100–150 MPa. Some Applications: Metals (Cu, Al, Ag, Ni, Cr, Mo, Sn, Ti, W, Be, etc.), Ceramics (Al2O3, MgO, ZrO2, HAp) Carbides (SiC, TaC, WC,ZrC), Nitrides (Si3N4, TaN, TiN), Borides (TiB2, LaB6, ZrB2), Flourides (LiF,CaF2, MgF2), Cermets, Intermetallic Compounds, etc.

Device Details

Place of Origin: China

Brand Name: Easyfashion Industry

Certification: CE Certificate

Model Number: EF-SPS-10T, EF-SPS-20T

Applicable Processing Products: Laboratory Research Usage

Usage: Sintering Furnace

Dimension(L*W*H): 3230mm,3200mm,2122mm (L,W,H) Ultimate Vacuum:: 10Pa

Rated Temperature: 2300°C Output Current: 5000A Or 10000A

Mold Size: 40mm, 60mm, 80mm And Max.100mm Voltage: 380V

Power(W): 20kW (adjustable)

Reviews

There are no reviews yet.