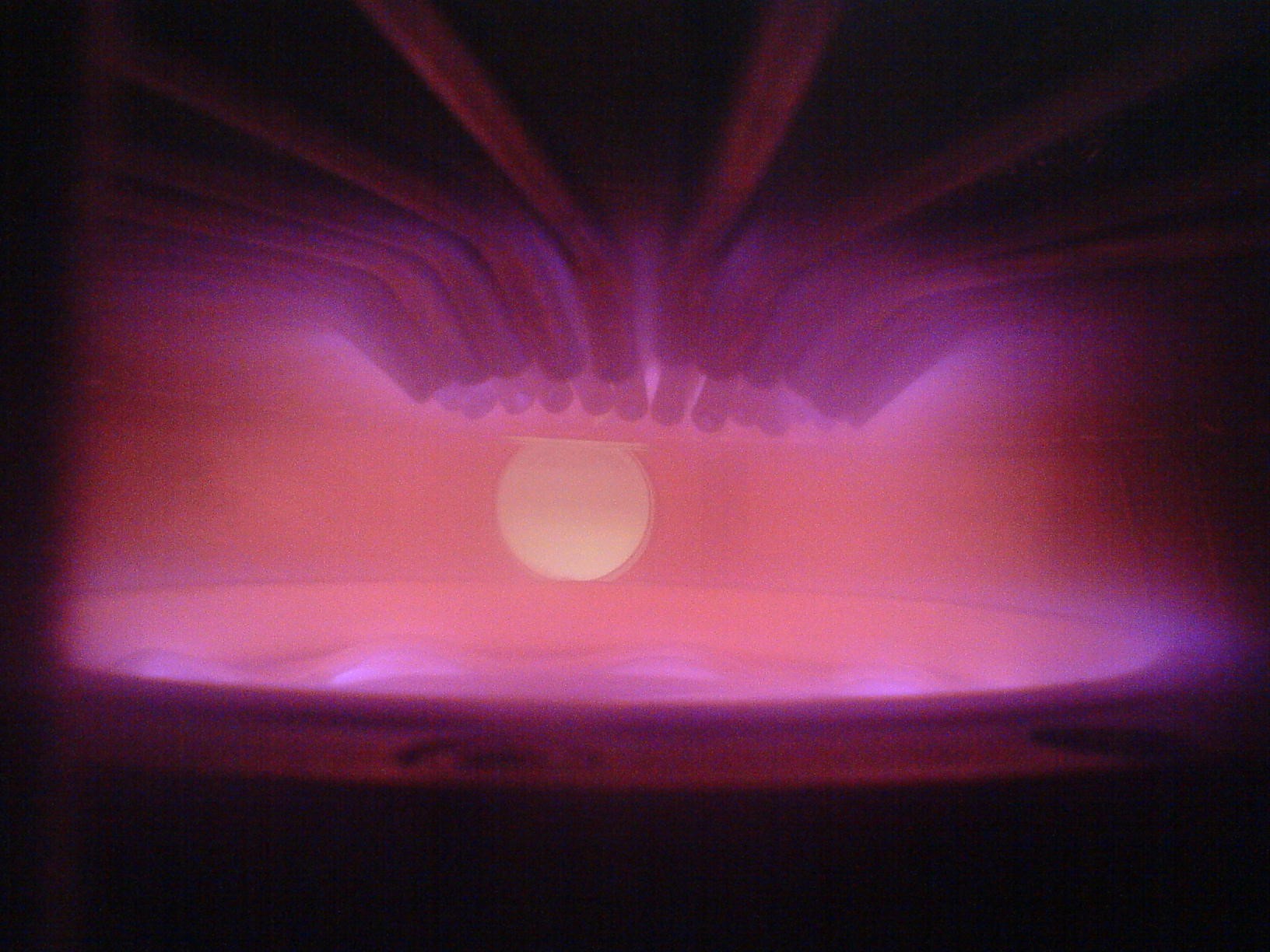

Plasma Enhanced Chemical Vapor Deposition (PECVD)

PECVD is a processing that placed considerable thin layer of any kind of material on substrate at low temperature. Required temperature is decreased as plasma reduce activation energy. One electrode is grounded and the other one is connected to RF generator. Plasma is formed between these two parallel electrodes. As result of capacitive coupling, input gas will becomes to plasma, chemical species is produced and thin film is decomposed on substrate. Substrate temperature can varied between room temperature and 350 C. System’s temperature is depend on the kind of decomposition. The description will be added later.

This product can control the layer stress by low/high frequency combination technique, has lower working temperature compare to conventional CVD systems, and using plasma cleaning of the chamber without any need to use toxic or wet chemicals. This PECVD system controls the stoichiometry of the process which gives the user the capacity to deposit of a wide range of materials including SiOx, SiNx, SiOxNy (applied to photonic structures, passivation, hard coatings …), a-Si:H, TEOS and SiO2, SiC, DLS deposition and several other materials suitable for variety of applications.

We can provide sample test before you buy.

Reviews

There are no reviews yet.