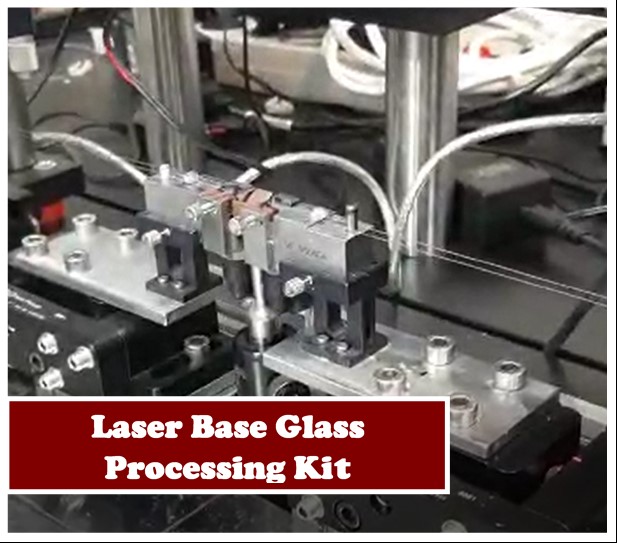

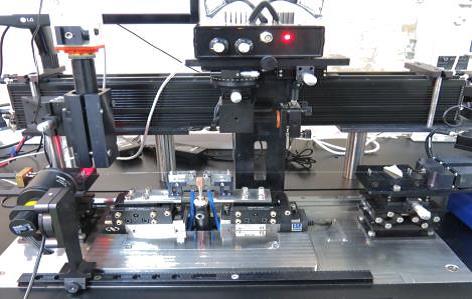

Laser Based Glass Processing Kit

Laser Base Glass Processing Kit is a glass processing and splicing system that uses a CO2 laser heat source to perform splicing and adiabatic tapering. The laser beam radiates vertically on the optical fiber by some optical components and then swept the optical fiber by using the galvanometer mirror and creates uniform heat over the hot zone region. Tapered fiber and splicing coupler with high symmetry and low loss are achieved using the adiabatic conditions.

Features:

- CO2 laser heat source is used for splicing and creating an adiabatic taper.

- Including optical components to focusing the laser beam on the optical fiber.

- Using the galvanometer mirror to create uniform heat over the hot zone region.

- Pre-written Labview program on PC for automatic operation.

- An advanced configurable system capable of producing tapers, microsphere, combiners, couplers, and splicing.

- 4-150mm travel Z motion for adiabatic tapers.

| Specification | Description |

| Fiber Heating and Splicing Source | CO2 laser |

| Fiber Observation Methods | CCD camera with 6X and 4X optics |

| Applicable Fiber Diameter |

|

| Fiber Handling | Custom fixtures to meet specific customer requirements |

| Alignment Methods |

|

| Maximum Taper Length | 150 mm |

| Minimum Taper Length | 4mm |

| Maximum Taper Ratio | 10:1 standard (For uniform direction, one-pass tapering) |

| Splicing Control | Internal firmware or operation by PC |

| Operating Conditions | 15-40°C |

| PM Fiber Alignment Methods | PAS (For PANDA and other PM fibers)

|

Be the first to review “Laser Based Glass Processing Kit”

Reviews

There are no reviews yet.